Cryovac packaging has become a game-changer in the food industry, offering advanced solutions for preserving freshness, extending shelf life, and enhancing product presentation. In today's competitive market, businesses are constantly seeking ways to improve their product quality and reduce waste. Cryovac technology addresses these challenges by providing innovative packaging methods that maintain the integrity of food items while improving their visual appeal.

This revolutionary packaging system utilizes vacuum-sealed techniques to create an airtight environment that minimizes oxygen exposure. By removing air from the packaging, Cryovac helps prevent the growth of aerobic bacteria and slows down the oxidation process, which are primary causes of food spoilage. As a result, food products remain fresher for longer periods, reducing waste and increasing profitability for businesses.

In this article, we will explore the ins and outs of Cryovac packaging, including its benefits, applications, and the science behind its effectiveness. Whether you're a food industry professional or simply curious about this cutting-edge technology, this guide will provide you with all the information you need to understand its significance and potential impact on modern food preservation practices.

Read also:Pop Melodie R34 Unveiling The Iconic Music Sensation

Table of Contents

- Introduction to Cryovac Packaging

- History and Development of Cryovac Technology

- The Science Behind Cryovac Packaging

- Key Benefits of Using Cryovac Packaging

- Applications Across Various Industries

- The Cryovac Packaging Process

- Cryovac vs. Traditional Packaging

- Sustainability and Environmental Impact

- Challenges and Limitations

- The Future of Cryovac Packaging

Introduction to Cryovac Packaging

Cryovac packaging represents a significant advancement in the field of food preservation and packaging. This innovative technology involves the use of vacuum-sealed bags to create an airtight environment that protects food from spoilage and contamination. The primary goal of Cryovac is to extend the shelf life of perishable items while maintaining their quality and nutritional value.

One of the standout features of Cryovac packaging is its ability to enhance the appearance of food products. By removing air and excess moisture, Cryovac creates a more appealing presentation that attracts consumers and increases sales potential. This makes it particularly popular in retail settings where visual appeal plays a crucial role in purchasing decisions.

Additionally, Cryovac packaging offers cost-saving benefits by reducing waste and improving inventory management. Businesses can store products for longer periods without compromising their quality, which leads to more efficient operations and higher profitability.

History and Development of Cryovac Technology

The origins of Cryovac packaging date back to the mid-20th century when vacuum-sealed packaging began gaining traction as a viable solution for food preservation. In the 1950s, the Cryovac division of W.R. Grace & Co. introduced the first vacuum-sealed bags specifically designed for the food industry. Over the decades, the technology has evolved significantly, incorporating advancements in material science, machinery, and sealing techniques.

Today, Cryovac is a global leader in vacuum-sealed packaging solutions, offering a wide range of products tailored to meet the diverse needs of various industries. The company continues to invest in research and development to improve the efficiency, sustainability, and effectiveness of its packaging systems.

The Science Behind Cryovac Packaging

At the core of Cryovac packaging lies the principle of vacuum sealing, which removes air from the packaging to create an oxygen-free environment. This process inhibits the growth of aerobic bacteria, mold, and yeast, which are primary contributors to food spoilage. Additionally, the absence of oxygen slows down the oxidation process, preserving the color, flavor, and texture of food items.

Read also:Tay Keith Net Worth The Untold Story Of Success And Influence

Another critical aspect of Cryovac technology is the use of specialized materials that provide superior barrier properties against moisture, gases, and external contaminants. These materials ensure that the vacuum-sealed environment remains intact throughout the product's shelf life, maintaining its freshness and quality.

Key Benefits of Using Cryovac Packaging

Cryovac packaging offers numerous advantages that make it an attractive option for businesses across various industries. Below are some of the key benefits:

- Extended shelf life for perishable items

- Improved product presentation and visual appeal

- Reduced waste and improved inventory management

- Enhanced food safety and protection against contamination

- Cost savings through more efficient operations

Applications Across Various Industries

Food Industry

The food industry is one of the primary beneficiaries of Cryovac packaging technology. From fresh produce to processed foods, Cryovac solutions are widely used to preserve the quality and freshness of various food items. Restaurants, grocery stores, and food processing plants rely on Cryovac to reduce waste, improve product presentation, and ensure consistent quality for their customers.

Retail Sector

In the retail sector, Cryovac packaging plays a crucial role in attracting consumers and increasing sales. The visually appealing presentation of Cryovac-sealed products makes them stand out on store shelves, encouraging impulse purchases. Additionally, the extended shelf life of these products allows retailers to maintain optimal inventory levels without worrying about spoilage or waste.

Healthcare Sector

Beyond the food industry, Cryovac packaging is also used in the healthcare sector for storing medical supplies, pharmaceuticals, and other sensitive materials. The airtight environment created by Cryovac ensures the sterility and integrity of these items, making it an essential tool for maintaining high standards of safety and quality in healthcare settings.

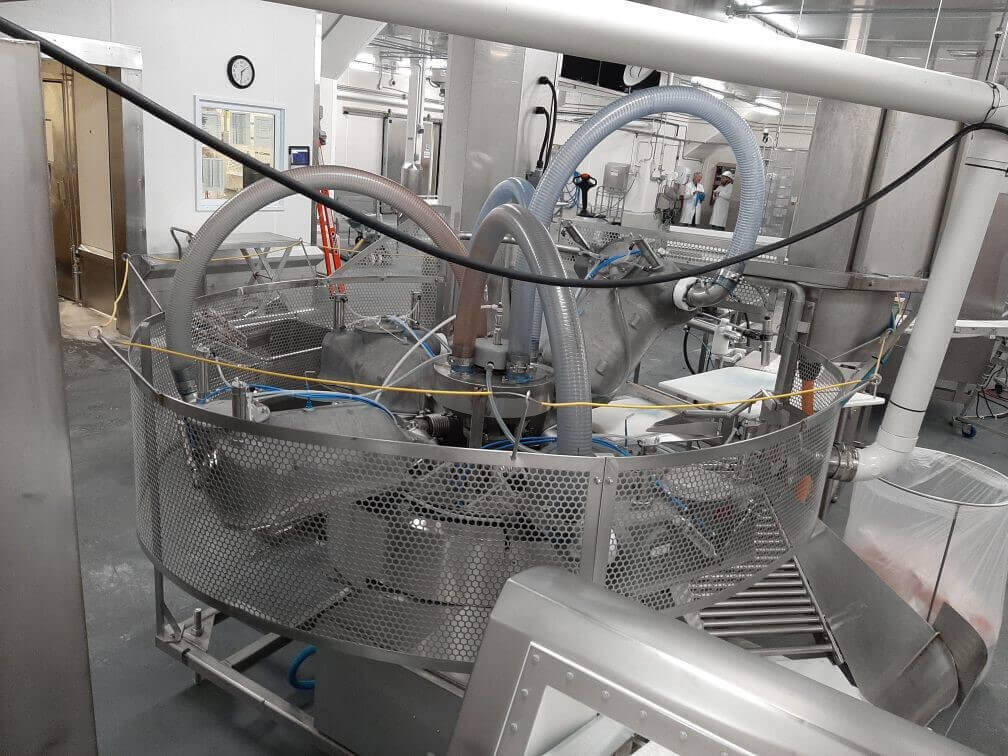

The Cryovac Packaging Process

The Cryovac packaging process involves several steps, each designed to ensure the highest level of quality and effectiveness. First, the product is placed inside a specially designed vacuum-sealed bag. The bag is then sealed using advanced machinery that removes air and creates an airtight environment. Finally, the sealed package is inspected for quality assurance before being distributed to customers.

This meticulous process guarantees that the packaged product remains protected from external factors that could compromise its quality or safety. By adhering to strict quality control standards, Cryovac ensures consistent results across all its packaging solutions.

Cryovac vs. Traditional Packaging

When compared to traditional packaging methods, Cryovac offers several distinct advantages. Unlike conventional packaging, which often allows air and moisture to penetrate the seal, Cryovac creates a completely airtight environment that significantly reduces the risk of spoilage and contamination. This results in longer shelf life and improved product quality.

Moreover, Cryovac packaging provides better protection against external factors such as temperature fluctuations, humidity, and physical damage. These features make it a more reliable and durable option for businesses seeking to enhance their packaging capabilities.

Sustainability and Environmental Impact

In recent years, sustainability has become a key concern for businesses and consumers alike. Cryovac packaging addresses this issue by offering eco-friendly solutions that minimize waste and reduce the environmental footprint of packaging materials. By extending the shelf life of products, Cryovac helps reduce food waste, which is a significant contributor to greenhouse gas emissions and environmental degradation.

Additionally, Cryovac is committed to developing sustainable packaging materials that are recyclable and biodegradable. The company collaborates with industry partners and environmental organizations to promote responsible packaging practices and reduce the overall impact of packaging on the environment.

Challenges and Limitations

While Cryovac packaging offers numerous benefits, it also faces certain challenges and limitations. One of the primary concerns is the initial cost of implementing Cryovac systems, which may be prohibitive for smaller businesses. However, the long-term savings achieved through reduced waste and improved efficiency often offset these initial expenses.

Another limitation is the need for specialized equipment and training to operate Cryovac machinery effectively. Businesses must invest in proper training and maintenance to ensure the optimal performance of their Cryovac systems.

The Future of Cryovac Packaging

As the demand for advanced packaging solutions continues to grow, Cryovac is poised to play a vital role in shaping the future of food preservation and packaging. With ongoing advancements in technology and material science, Cryovac is likely to become even more efficient, sustainable, and cost-effective in the coming years.

Furthermore, the increasing focus on sustainability and environmental responsibility will drive the development of eco-friendly Cryovac solutions that align with global efforts to reduce waste and minimize the environmental impact of packaging materials.

Conclusion

Cryovac packaging has revolutionized the way businesses approach food preservation and packaging. By offering innovative solutions that extend shelf life, improve product quality, and reduce waste, Cryovac has become an indispensable tool for industries ranging from food production to healthcare. Its ability to create airtight environments that protect against spoilage and contamination makes it a superior alternative to traditional packaging methods.

As we look to the future, Cryovac is expected to continue evolving and adapting to meet the changing needs of businesses and consumers. By embracing sustainable practices and investing in cutting-edge technology, Cryovac will remain at the forefront of the packaging industry, delivering exceptional value and reliability to its users.

We invite you to share your thoughts and experiences with Cryovac packaging in the comments section below. Your feedback and insights will help us better understand the impact and potential of this groundbreaking technology. Additionally, we encourage you to explore other articles on our site for more information on related topics and trends in the food and packaging industries.