Cryovac packaging has become an indispensable solution for businesses aiming to preserve food quality, extend shelf life, and enhance product presentation. As consumer demand for fresh, convenient, and sustainable products grows, understanding this innovative packaging technology is essential for companies in the food and beverage sector. In this article, we will explore the benefits, applications, and advancements of Cryovac packaging, offering valuable insights for businesses and consumers alike.

Cryovac packaging is not just another packaging solution; it represents a breakthrough in preserving the integrity of perishable goods. Its ability to maintain freshness, reduce waste, and improve operational efficiency has made it a game-changer for industries worldwide. Whether you're a business owner, supply chain professional, or simply a curious consumer, this article will provide you with the knowledge you need to understand why Cryovac packaging is so effective.

From its origins to the latest technological advancements, Cryovac packaging continues to evolve, meeting the demands of modern markets. In the following sections, we will delve into the technical aspects, applications, and benefits of this innovative technology. Let's explore how Cryovac packaging can transform your business and contribute to a more sustainable future.

Read also:Milly Alcock Feet Exploring The Rising Stars Journey And Beyond

Table of Contents

- Introduction to Cryovac Packaging

- The History and Evolution of Cryovac Packaging

- Benefits of Cryovac Packaging

- Types of Cryovac Packaging

- Applications Across Industries

- Environmental Impact and Sustainability

- The Technology Behind Cryovac Packaging

- Cost Considerations and ROI

- Challenges and Solutions

- The Future of Cryovac Packaging

Introduction to Cryovac Packaging

Cryovac packaging refers to a vacuum-sealed packaging system designed to preserve the freshness and quality of perishable goods, particularly food products. This method removes air from the packaging, reducing oxidation and preventing the growth of bacteria, thereby extending the shelf life of the product. Cryovac packaging is widely used in the food and beverage industry, offering businesses a reliable solution for maintaining product integrity and reducing waste.

This innovative technology has transformed the way companies handle perishable goods, enabling them to meet the growing demand for high-quality, fresh products. By creating an airtight seal, Cryovac packaging ensures that products remain in optimal condition throughout the supply chain, from production to consumption.

Key Features of Cryovac Packaging

Cryovac packaging offers several key features that make it an attractive option for businesses:

- Airtight seals that prevent contamination

- Extended shelf life for perishable goods

- Enhanced product presentation and branding

- Reduced waste and operational costs

The History and Evolution of Cryovac Packaging

The concept of vacuum-sealed packaging dates back to the early 20th century, but it wasn't until the 1970s that Cryovac packaging emerged as a commercial solution. Developed by Sealed Air Corporation, Cryovac packaging quickly gained popularity due to its ability to preserve food quality and reduce spoilage. Over the years, the technology has evolved, incorporating advancements in materials, machinery, and processes to meet the needs of modern industries.

Major Milestones in Cryovac Packaging

Throughout its history, Cryovac packaging has achieved several milestones that have shaped its development:

- 1970s: Introduction of vacuum-sealed packaging for food preservation

- 1990s: Expansion into other industries, including healthcare and retail

- 2000s: Adoption of sustainable materials and eco-friendly practices

- 2020s: Integration of smart packaging technologies and automation

Benefits of Cryovac Packaging

Cryovac packaging offers numerous benefits for businesses and consumers alike. By preserving product quality and extending shelf life, it reduces waste, improves operational efficiency, and enhances customer satisfaction. Additionally, Cryovac packaging provides businesses with a competitive edge in an increasingly demanding market.

Read also:Pop Melodie R34 Unveiling The Iconic Music Sensation

Top Benefits for Businesses

- Reduced spoilage and waste

- Improved product presentation and branding

- Enhanced supply chain efficiency

- Increased customer loyalty and satisfaction

Types of Cryovac Packaging

Cryovac packaging comes in various forms, each tailored to specific applications and industries. Understanding the different types of Cryovac packaging can help businesses choose the most suitable solution for their needs.

Common Types of Cryovac Packaging

- Vacuum-sealed bags for food preservation

- Modified atmosphere packaging (MAP) for fresh produce

- Shrink films for product bundling and presentation

- Thermoformed trays for ready-to-eat meals

Applications Across Industries

Cryovac packaging is widely used across various industries, including food and beverage, healthcare, retail, and logistics. Its versatility and effectiveness make it an ideal solution for businesses seeking to improve product quality and reduce waste.

Industry-Specific Applications

Here are some examples of how Cryovac packaging is applied in different industries:

- Food and Beverage: Preserving freshness and extending shelf life

- Healthcare: Protecting medical devices and pharmaceuticals

- Retail: Enhancing product presentation and branding

- Logistics: Ensuring product integrity during transportation

Environmental Impact and Sustainability

As environmental concerns continue to grow, businesses are increasingly seeking sustainable solutions for their packaging needs. Cryovac packaging addresses these concerns by reducing waste, improving resource efficiency, and incorporating eco-friendly materials.

Sustainable Practices in Cryovac Packaging

Some of the sustainable practices adopted in Cryovac packaging include:

- Use of recyclable and biodegradable materials

- Reduction of food waste through extended shelf life

- Optimization of logistics and transportation processes

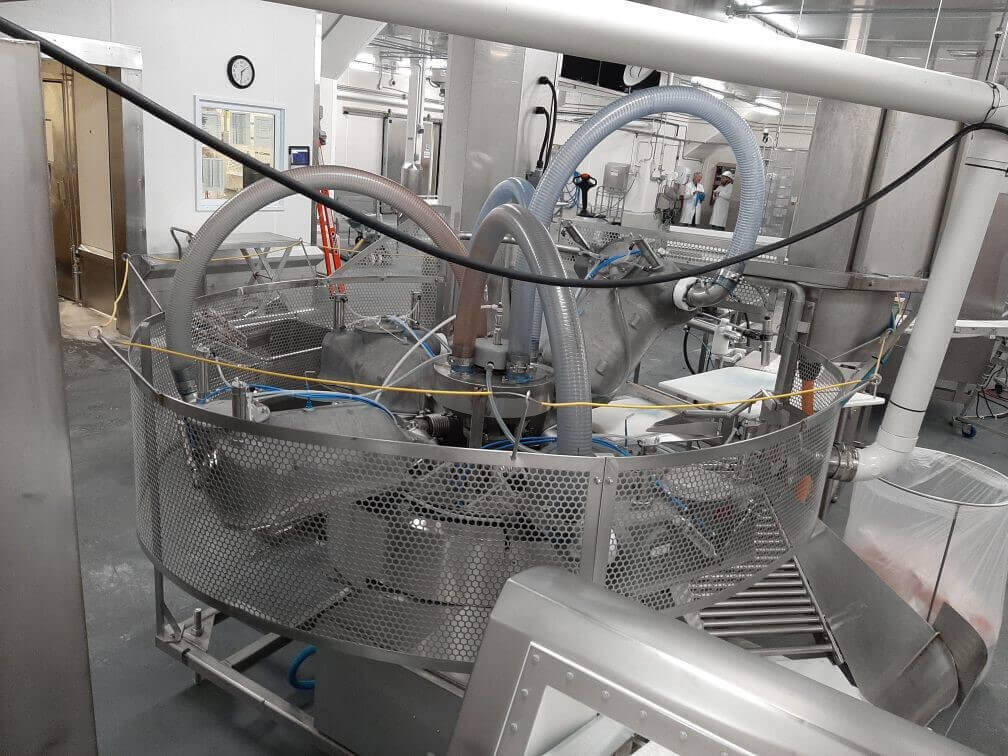

The Technology Behind Cryovac Packaging

Cryovac packaging relies on advanced technology to ensure optimal performance and effectiveness. From vacuum-sealing machines to smart packaging solutions, the technology behind Cryovac packaging continues to evolve, offering businesses cutting-edge tools to enhance their operations.

Key Technologies in Cryovac Packaging

Some of the key technologies used in Cryovac packaging include:

- Vacuum-sealing machines for airtight packaging

- Modified atmosphere systems for fresh produce

- Smart packaging solutions for real-time monitoring

Cost Considerations and ROI

While Cryovac packaging may require an initial investment, its long-term benefits often outweigh the costs. By reducing waste, improving efficiency, and enhancing product quality, Cryovac packaging can deliver significant returns on investment for businesses.

Factors Affecting Cost

Several factors influence the cost of Cryovac packaging, including:

- Type of packaging material and machinery

- Volume and frequency of production

- Customization and branding requirements

Challenges and Solutions

Despite its many advantages, Cryovac packaging does face certain challenges, such as initial costs, technical requirements, and environmental concerns. However, these challenges can be addressed through innovative solutions and best practices.

Addressing Common Challenges

Some strategies for overcoming challenges in Cryovac packaging include:

- Investing in cost-effective materials and machinery

- Implementing training and support programs for employees

- Adopting sustainable practices and eco-friendly materials

The Future of Cryovac Packaging

As technology continues to advance and consumer demands evolve, the future of Cryovac packaging looks promising. Innovations in materials, machinery, and processes will further enhance its effectiveness and sustainability, ensuring its relevance in the years to come.

Trends Shaping the Future of Cryovac Packaging

Some of the trends expected to shape the future of Cryovac packaging include:

- Increased adoption of smart packaging technologies

- Greater emphasis on sustainability and eco-friendly practices

- Expansion into new industries and applications

Conclusion

Cryovac packaging has proven to be a transformative solution for businesses in the food and beverage industry, offering numerous benefits in terms of product preservation, operational efficiency, and environmental sustainability. By understanding its history, applications, and advancements, businesses can make informed decisions about implementing Cryovac packaging solutions to meet their unique needs.

We encourage you to explore the possibilities of Cryovac packaging for your business and consider how it can contribute to your success. Don't hesitate to leave a comment or share this article with others who may benefit from the insights provided. For more information on Cryovac packaging and related topics, be sure to check out our other articles on the website.